Material wood

Japanese Cedar / Japanese Cypress

Tanihata Kumiko is basically made from two types of wood: Japanese Cedar from Tohoku and Hokuriku and Japanese Cypress from Nagano or Gifu. Japanese Cedar features beautiful grain, and develops character with use. Japanese Cypress is much favored in Japan and is well known for its durability, as evidenced by its use in the Horyuji temple, one of the oldest temples in Japan.

Basic Woods

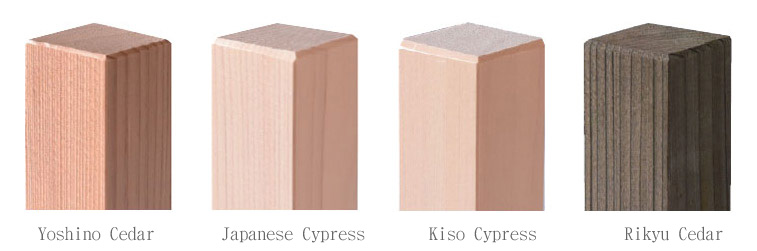

| Wood | Source | Feature | Color | Price range |

|---|---|---|---|---|

| Yoshino Cedar | Kawakami in Nara | This wood is highly regarded by their dense growth rings and beautiful color without knots as well as interior materials. Tanihata selects only good quality timber from heart – wood to use. | Light white ~ Pink | ★★ |

| Japanese Cypress Genpei wood | Tono in Gifu | Tono has been a production area of Japanese Cypress since 14th century. Woods from Tono is what our company uses the most because of their stable quality. | Light white ~ Pink | ★★ |

| Kiso Cypress Genpei wood | Kiso in Nagano | That is a high grade product of Japanese Cypress with noble aroma and beautiful bark. They are used for famous shrines, temples and castles all over Japan. | Light white ~ Pink | ★★★★ |

| Rikyu Cedar | Toyama and Hokuriku region | This is our original wood soaked in a solution developed by Tanihata, affecting wood components to color. No chemicals or paints are included. With elegance like an old tearoom, we bring out the charm from cedar. It goes well with rooms in dark brown tone. *Trade – mark applied for. | Dark brown ~ Greyish brown | ★★★★ |

Special Woods ( For the Art Kumiko and the Asanoha Chirashi “Type TA” only )

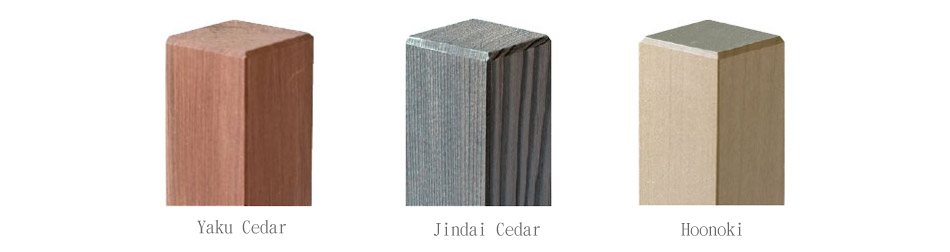

| Wood | Source | Feature | Color | Price range |

|---|---|---|---|---|

| Yaku Cedar | Yaku island in Kagoshima | Yaku cedar is a naturally-grown cedar more than 1000 years old in Yakushima Island, a World Natural Heritage site. Currently, felling these trees is prohibited. We use buried trees of Edo era (from 17th to middle of 19th century). They are quite rare with elaborate grains and abundant resin. | Brown | ★★★★★ |

| Jindai Cedar | Throughout Japan | Buried for more than 2000 years, its color has changed to greyish brown due to aging. It is recommendable for a monotone interior and partial use in art Kumiko. | Greyish brown ~ Brown | ★★★★★ |

| Hoonoki | Throughout Japan | This is a broad-leaved magnolia family with less cracks and distortion. As it is said that it has a character to keep a sword free from rust, it has been used for scabbards in Japan. Pale green barks widen a range of expression in art Kumiko. | Light green | ★★★★ |

From the perspective of environmental issues, Tanihata stopped using import timbers to change over to domestic ones for main materia ls from Kiso area in Nagano prefecture, Tono area in Gifu prefecture and Yoshino area in Nara prefecture as well as Cypress and cedar from Hokuriku district.

Japanese Cedar

What is Japanese Cedar?

Japanese Cedar, Cryptomeria japonica, meaning “Japanese hidden treasure” In use since the Jomom era, this is one of the most popular planted trees in Japan, it reaches maturity in 60 – 80 years.

The well known Japanese Cedar comes from Akita, Yoshino and Yakushima. Wood suitable for Kumiko is carefully selected piece by piece.

Tanihata only uses the selected wood as below:

- Wood with straight grain.

- Wood with fine grain. Larger trees are selected for their beautiful grain, which however, occurs in only part of the tree.

- Wood with beautiful coloring. As Kumiko is not painted, the natural wood color must be beautiful. It also needs to be capable of being planed to a fine smooth surface.

Japanese Cedar comes in a variety of colors but reddish or light brown is preferred. Fine grained Japanese Cedar becomes more beautiful with use.

What is Jindai Cedar?

Jindai Cedar is wood that has remained underground for hundreds, or even thousands, of years. This valuable wood has remained miraculously undecayed, buried in lake beds or marsh since a time of volcanic activity in the past.

Over time the wood colour changed to black, giving it a very beautiful appearance.

Unfortunately, Jindai Cedar is rarely supplied to the market because of its scarcity, and dark colored Kuro Jindai is extremely rare.

We keep only limited stock of Jindai Cedar, so please contact us if you wish to place an order.

Japanese Cypress

What is Japanese Cypress?

Japanese Cypress has been used for palaces, temples and shrines in Japan as it has long term durability.

The Horyuji temple, one of the oldest temples in Japan, has still used the Japanese Cypress applied for its construction more than1,300 years ago. In rebuilding the temple in 1944, to be surprised, the Cypress was found to be smelled as a fresh one. Its smooth and fine touch, pleasant smell and beautiful appearance is favored by many Japanese.

Two types of Japanese Cypress are available: Genpeizai meaning a combination of red and white, from Gihu, consists of 70% reddish heartwood and 30% white sapwood. Kiso Cypress has only heartwood. Genpeizai is recommended due to its lower cost, and because there is little difference in color between the heartwood and sapwood.

In the film “Katen no Shiro” which tells the story of building a castle for General Nobunaga, it is said that a Cypress is worth a man’s life because cutting a Cypress tree without permission incurs the death penalty. It is noted that a master builder takes great care in selecting his wood.

Since no other wood equals mature Kiso Cypress (up to 280 years old), with its unique smell, glossy texture and beautiful grain, it was used in the construction of historical shrines including the Ise Jingu and Izumo Taisha Shrines.

As government regulations control forest entry and harvesting of Kiso Cypress, it is not available on the market, and therefore, is not used for Kumiko production.

However, Tanihata has special access to be able to obtain Kiso Cypress and hold some in stock.

The natural essence taken from Cypress is “hinokitiol”. Hinokitiol has a strong antibacterial function which resists the growth of mold and helps to relieve atopic dermatitis.

Due to its aromatic quality, Kiso Cypress is used as a relaxant, and visitors to our factory always appreciate the smell the wood exudes.

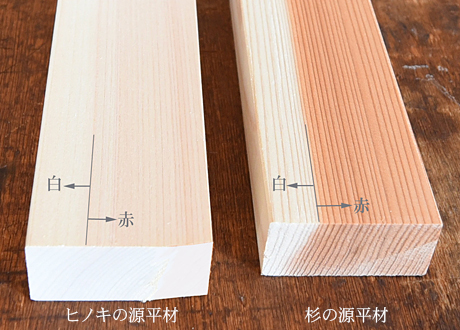

What is Genpeizai?

The center wood or heartwood is reddish in color, the outer sapwood is white.

Wood that combines both heartwood and sapwood is known as Genpeizai.

The name comes from the ancient battle in the Kamakura era in which the “Gen ji” side carried white flags, while the “Hei (Pei) ke” side carried red flags.

Genpeizai is highly recommended because of the slight difference in colour between the heartwood and sapwood.

Japanese timber is the main material used in Kumiko products.

For details, please see the “Global Warming Countermeasures” page.

Characteristics of Wood

It is said that wood, more than other materials, “breathes” and “grows” in response to its surroundings. In particular, unpainted wood responds to humidity by expanding. And the soft sweet smell of natural wood gives long lasting pleasure.

The color of natural wood is also appealing to the eye. Since we are surrounded by harsh concrete walls and buildings, we can appreciate the color, texture, smell and atmosphere that natural wood imparts.

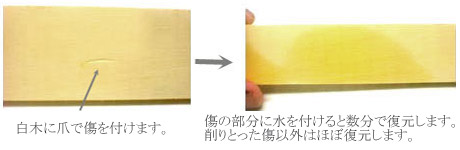

Natural wood has the ability to restore itself as you can see from the picture. Its ”breathing,” is both an advantage and disadvantage.

Articles made from wood respond subtly to a number of outside factors, for example, the dry climate of the Pacific side of Japan, the rainy and snowy Japan Sea side, the season and location, and whether it is indoors or outside.

Although a craftsman carefully selects dry wood for use, natural materials sometimes warp later when used outdoors.

The possibility that warping may occur, should be understood prior to purchase. If serious warping occurs, we are prepared to exchange the products.

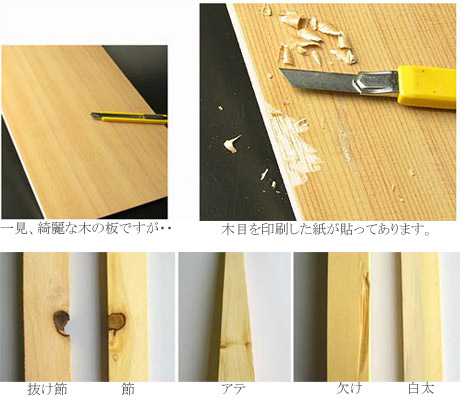

Most products on the market nowadays are made of composite board, that is fabricated board such as ply MDF and LVL, with printed vinyl chloride and paper on the surface to give the appearance of real wood.

These fabricated wood products are used for doors and frames. Through advanced printing technology, surface irregularities can produce the effect of natural wood at first glance (see the pictures ).

You might like to take a careful look at the doors of your house!

Printed fabricated board has none of the features of real wood, though it does have durability, making it suitable for lower cost mass production. Higher quality fabricated board has a wood veneer.

We differentiate between low quality fabricated board and the natural wood that is normally used for our products.

Experienced Craftsmen Sort and Select Wood

We make all our products, Ramma (transoms), room dividers and fittings, from coniferous wood. Kumiko products are made of beautiful conifer wood planed to a fine finish.

Given that warping is the main disadvantage of natural coniferous wood, selection of the right wood for the product is of the utmost importance. It is not easy to select wood that will not warp.

The grain and weight of the wood is checked, and consideration given to its temperature, as warping tends to occur more commonly in wood that has a low temperature.

Although most wood varieties have shortcomings, a skilled craftsman can make the most of his material through understanding its characteristics and the applications for which it is suited. The process of wood working includes not only the creation of the product, but also selection of the appropriate wood for the task. Big manufacturing companies use low-cost wood and fabricated materials in order to increase operational efficiency and reduce customer complaints regarding warping.

If it is thought that wooden products are merely consumable goods, fabricated wood items may be acceptable.

But we are committed to creating useful, beautiful and long lasting products, ensuring that the customer receives value for money.

After the wood has been sawn to size, it is planed smooth, as shown in the picture. This is not the case in low-cost production, where only wood with a particularly rough surface is planed. Sandpaper is sometimes used for the surface finish. Ramma (transoms) is normally planed.